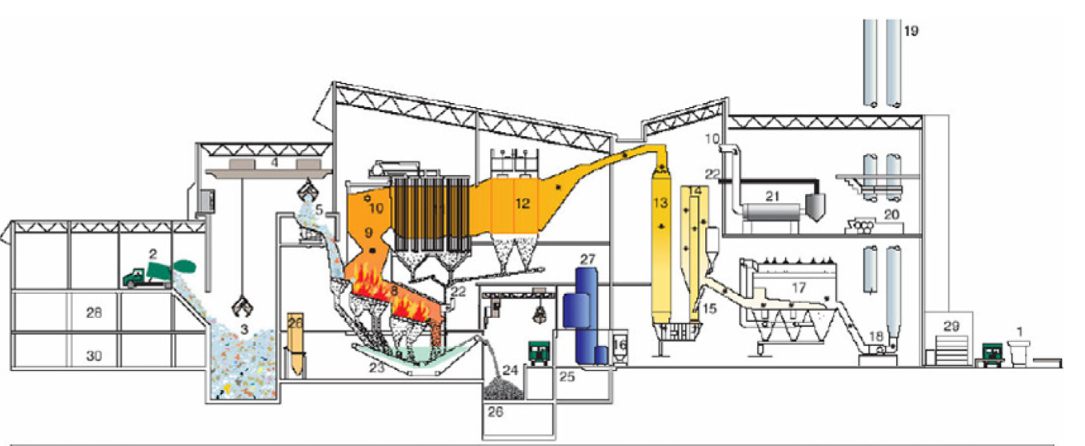

In mid-July I met with a Sheffield-based architect, specialised in Energy-from-Waste facilities. Below are some key points in relation to the various stages of such projects.

Pre-planning: Operator (sponsor) hires a design team (architect, SE, Services, planning, historic, PR, highways, transport)

Architect designs based on experience; no guidance . It is more efficient to have a vertical boiler but horizontal is often required by planning because the building would be lower.

Risks: refusal. Sometimes the local authority gives a permission but the secretary of state rejects. Environmental agency involved throughout

Post-planning / delivery: Operator appoints EPC contractor – based on a tender. EPC contractors provides specification and sizes / requirements of the proposed plant kit.

Risks: Plant equipment will not fit within the parameters, approved at planning.

Sometimes tender is done based on simplistic early stage drawings which puts the building contractor at risk (not to confuse with the EPC contractor!).

Construction: EPC contractor finds a building contractor. EPC and BC sign a contract – Design & Build (NEC 3 / 4); with warranties back to the Sponsor (operator).

Various risks associated with large infrastructural projects: eg. connecting to the national grid (why Clogston (Colston?) went bust, look up Clogston vs CNIM.

Post-construction: It typically 12-14 months to commission a plant – to ensure due operation, to pass the necessary environmental certifications.

Other notes:

My interviewee agreed there is little innovation in teh EfW sector – plants are the same as 20 years ago. The key progress is in efficiency. Efficiency depends on the number and capacity of the lanes. EPC would want to take as much waste as possible through a single lane.

Transporting waste is best if not done by road – eg. Wilton (train); Cory facilities along the Thames (barges from c. London). My interviewee is currently involved with a new such facility next to exg. one which took 10 years to get planning.

Carbon capture will be very prominent in the future. UK Gov recommendation to pump under the sea using gas and oil rigs. Places near the coast are more fortunate. Multiple facilities will be joined by pipes to pump the CO2 across the country and down under the sea.

Alternative technologies for treating general waste are risky. There is a handful in the UK. Surrey, Milton Keynes, Isle of Wight (?), latter two by Sesper (like Suez or Biffa in gasification world)

Scotland & Wales governments decided to build no more EfW facilities in the respective countries. Alternative options could be exporting waste, using gasification, hoping waste quantities reduce and no new plants are needed.